Troubleshooting Defects in Printer Output

Description

Loftware products support a wide variety of printers. Most of the printed label or page content is generated at the printer and is not an image. Because of this, if there are printing defects on the label, then the issue likely lies with the printer itself. This article discusses common types of problems and their solutions.

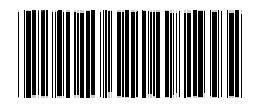

Jagged Edge (single)

Cause: Print speed is too high

Solution: Reduce the print speed. Within Loftware products, ensure that the label design is not overriding the printer setting or the Loftware setting is correct.

Cause: Defective media

Solution: Replace ribbon or label stock. When troubleshooting, replace one at a time to be sure which is causing the issue.

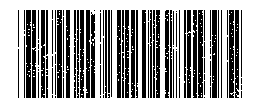

Jagged Edges (both)

Cause: Print speed is too high

Solution: Reduce Print Speed incrementally until the desired definition is achieved. Within Loftware products, ensure that the label design is not overriding the printer setting or the Loftware setting is correct.

Cause: Ribbon not compatible with label stock

Solution: Replace either the ribbon or the label stock to a compatible combination.

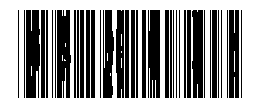

Light Edges

Similar to jagged edges, but there is still some imprinting at the edges, it is not completely unprinted

Cause: Slew Rate is too high

Solution: Reduce Slew Rate incrementally until the desired definition is achieved. Within Loftware products, ensure that the label design is not overriding the printer setting or the Loftware setting is correct.

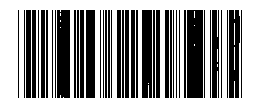

Underburn

Cause: Insufficient or uneven pressure is being applied to the media

Solution: Adjust the print head pressure (or in some cases, change the print head).

Cause: Heat is insufficient when printing to the media

Solution: Increase temperature incrementally until the desired definition is achieved. Within Loftware products, ensure that the label design is not overriding the printer setting or the Loftware setting is correct.

Overburn

Cause: Heat is excessive when printing to the media

Solution: Reduce temperature incrementally until the desired definition is achieved. Within Loftware products, ensure that the label design is not overriding the printer setting or the setting in Loftware is correct.

Unable to sustain wide:narrow ratio

Cause: Bars are too thick as a result of Overburn, or too narrow as a result of Underburn

Solution: See Overburn and Underburn.

Cause: Barcode's ratio is too small. As symbols become smaller, reading tolerances become more acute.

Solution: Create symbols with the highest wide-to narrow ration that the label space or the specification allows.

Spots or Voids

Cause: Print head is dirty

Solution: Clean print head (see printer's manual for more information).

Cause: Print head has a burnt out element

Solution: Replace print head.

Cause: Ribbon is wrinkled

Solution: Straighten ribbon. Ribbon tension made need to be increased. If ribbon wrinkling occurs regularly, then the print speed may need to be reduced.

Cause: Defective media

Solution: Replace media.

Unwanted Lines

Cause: Media is wrinkled

Solution if the ribbon is wrinkled: Straighten ribbon. Ribbon tension made need to be increased. If ribbon wrinkling occurs regularly, then the print speed may need to be reduced.

Solution if the label stock is wrinkled: Verify that there are no more wrinkles in the label stock. If there are more wrinkles, replace label stock.

Cause: Defective Media

Solution: Replace ribbon or label stock. When troubleshooting, replace one at a time to be sure which is causing the issue.

Article Number

2014004

Versions

All Loftware products using Thermal Printers

Environment

All supported Thermal Printer installation environments.